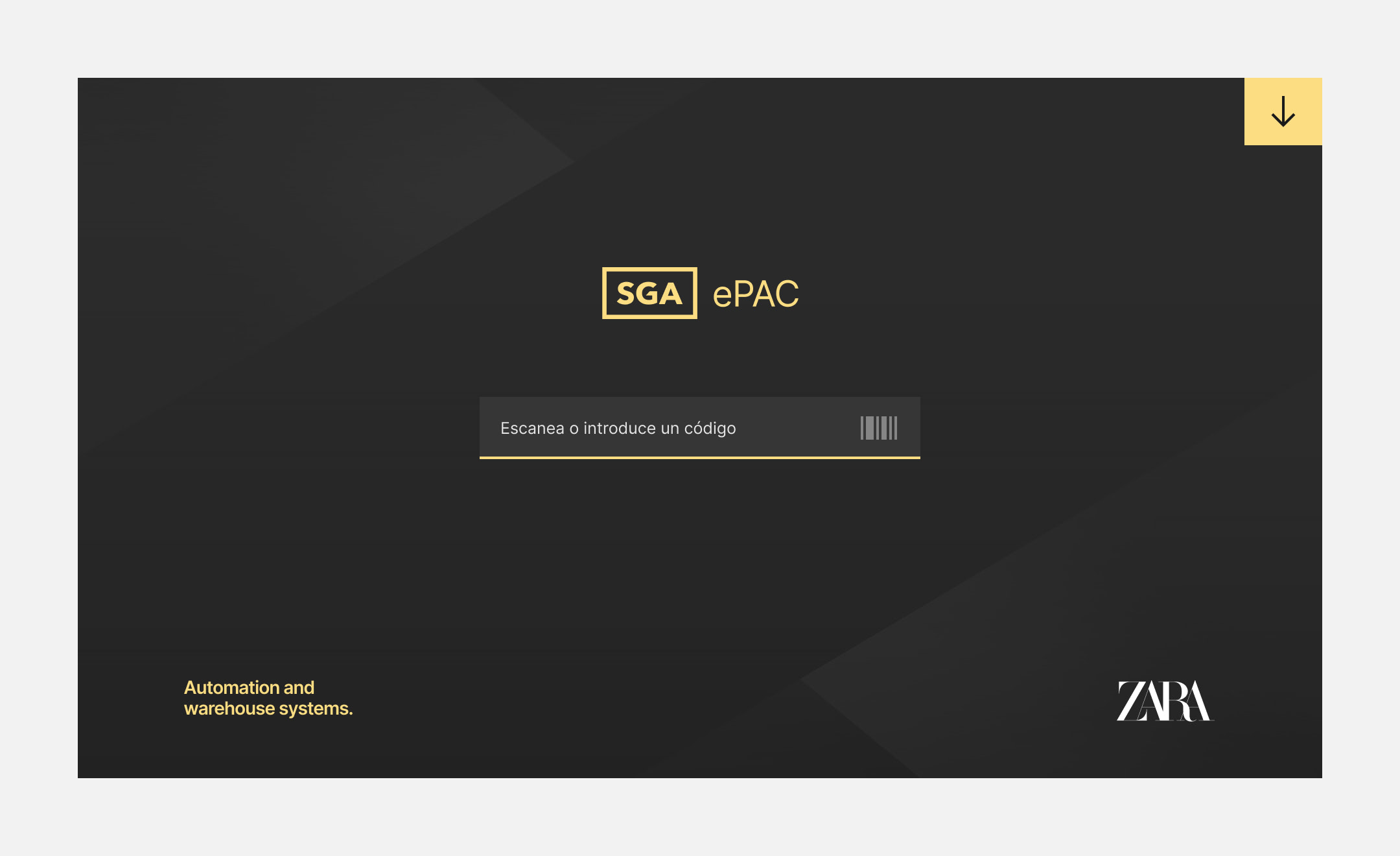

ZARA EPAC

TOUCHING EFFICIENCY — COMPREHENSIVE TOUCHSCREEN TOOL FOR SUPPORT, TRACKING AND OPTIMIZATION OF PACKAGING STATIONS FOR ORDERS PLACED THROUGH ZARA.COM

Client

Inditex

Year

2020

Role

Product Designer

What I did

Research, analysis and product design

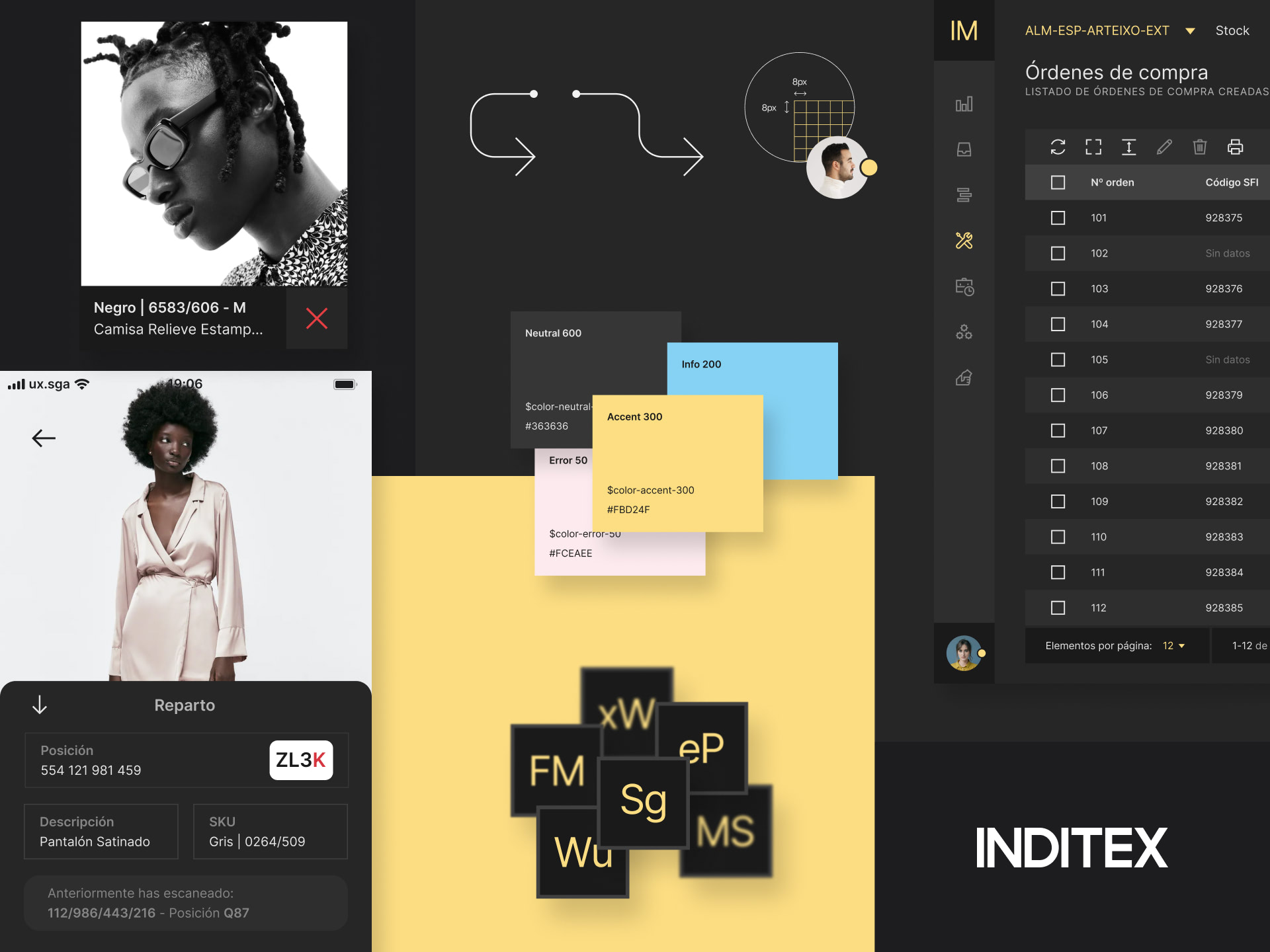

Any manual process is susceptible to errors, and order preparation is not exempt from this challenge. A digital tool that oversees the situation consistently becomes indispensable in an environment where efficiency is paramount. Encountering an attempted application that did not even consider the intended device type, I seize the opportunity presented by the new SGA branding and the NOA Design System to breathe life into a new solution.

This touchscreen order preparation system has been meticulously designed as an integral tool to enhance efficiency and precision in packaging stations, initially focused on Zara and subsequently intended for implementation across all Inditex chains. It provides a uniform and advanced solution for order management.

The platform enables the swift identification of products through scanning and the integrated technology automatically locates the potential orders to be prepared. Once the order is selected, it offers comprehensive tracking of the process, from choosing packaging to managing possible issues. Continuous access to all order data and its products significantly streamlines the packer's task, ensuring accuracy at every step.

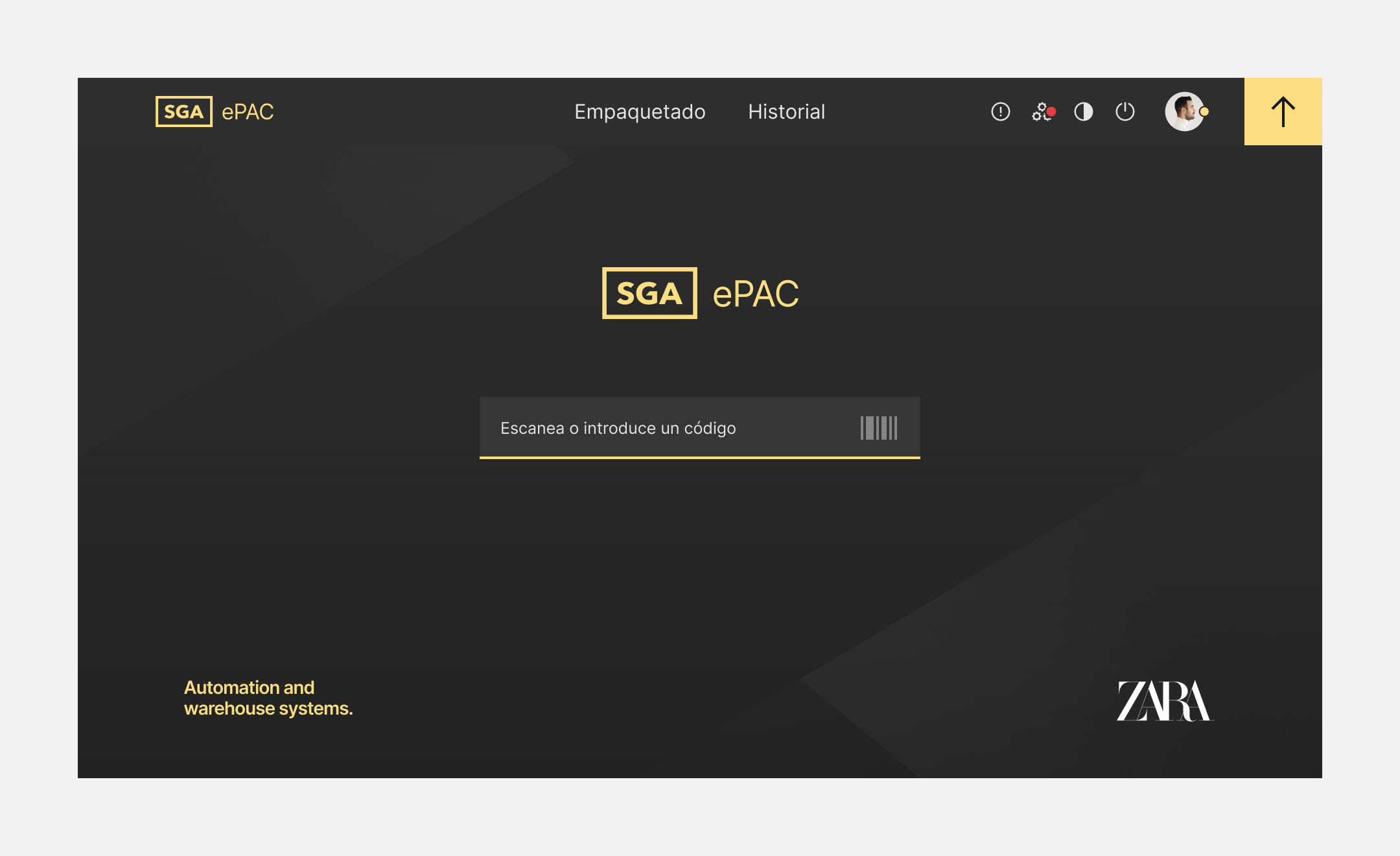

The final product design reflects the new identity of SGA and seamlessly adapts to current and future touchscreen displays in warehouses. This ensures visual appeal, speed, and user-friendliness — critical elements in a task where the primary goal is to efficiently complete the maximum number of orders throughout the day.

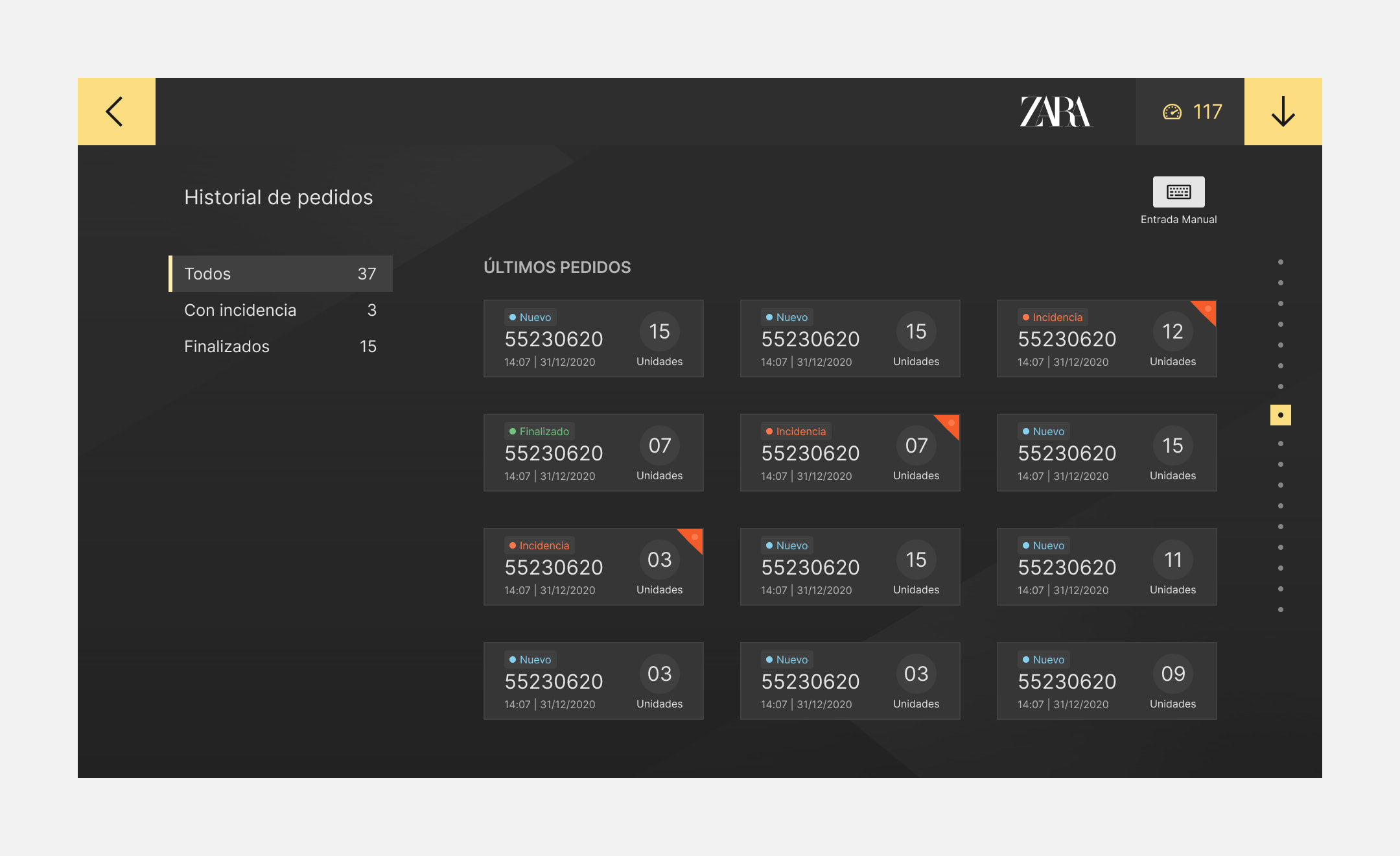

Product scanning, access to order history, notifications, platform settings, and user profile.

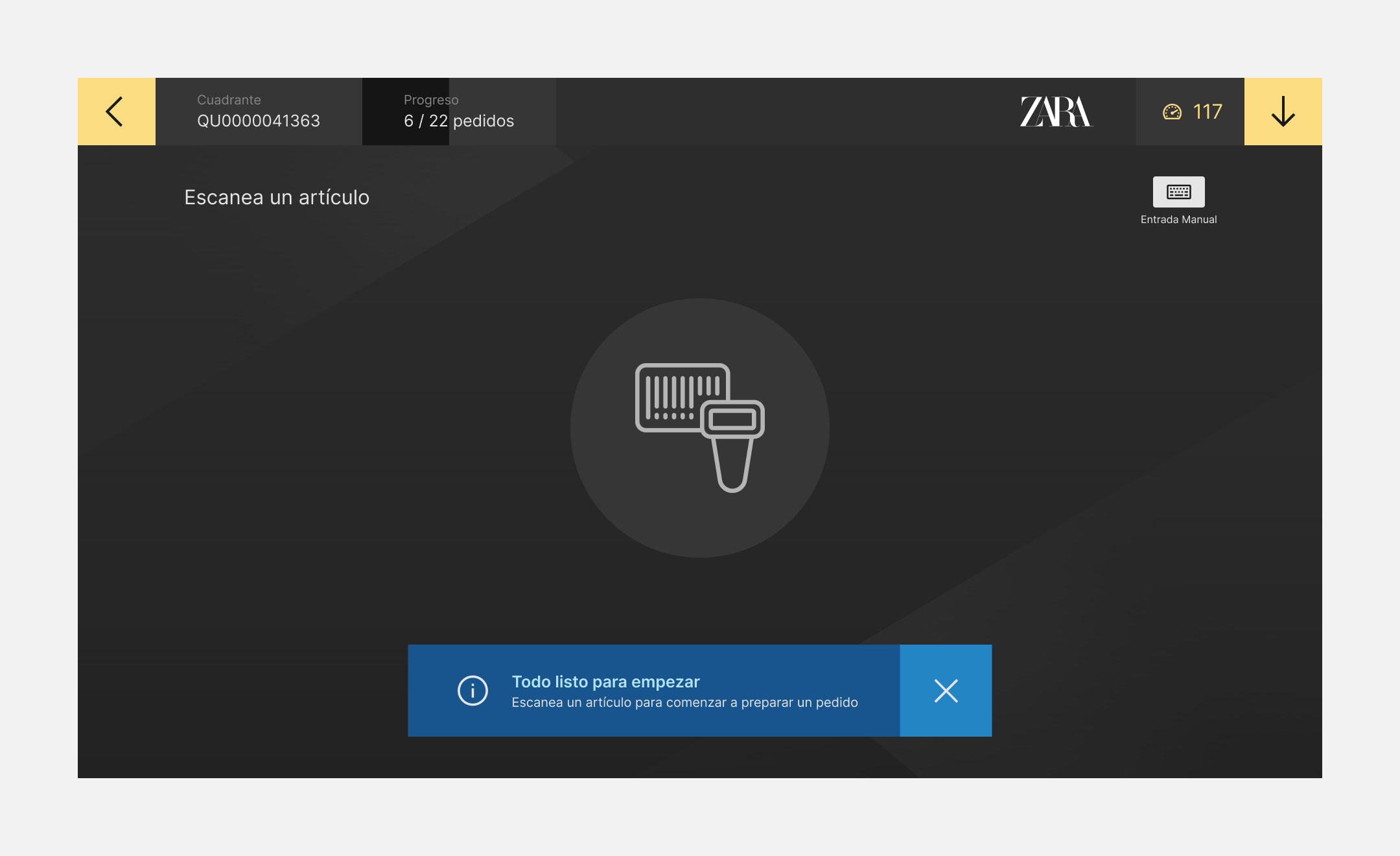

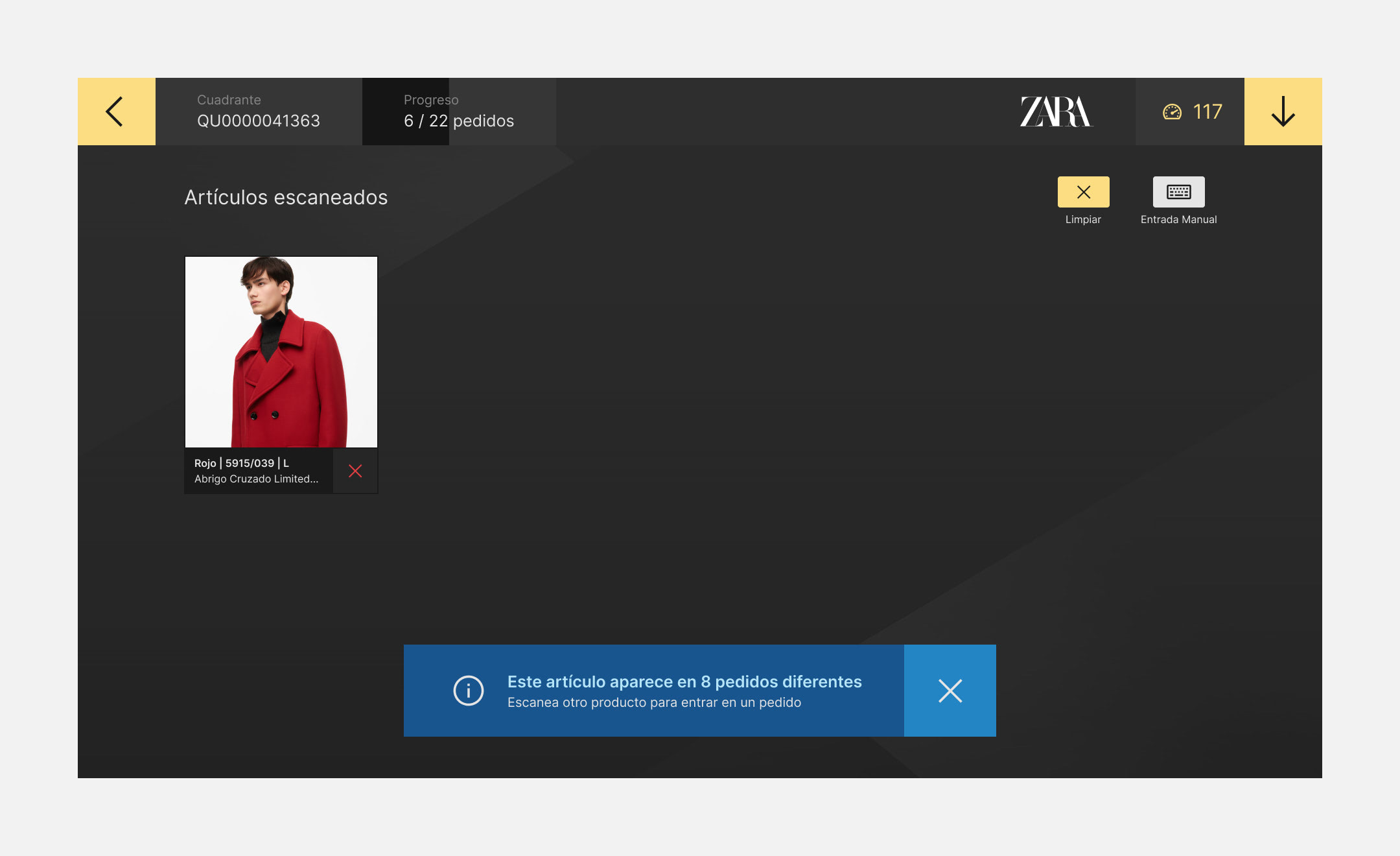

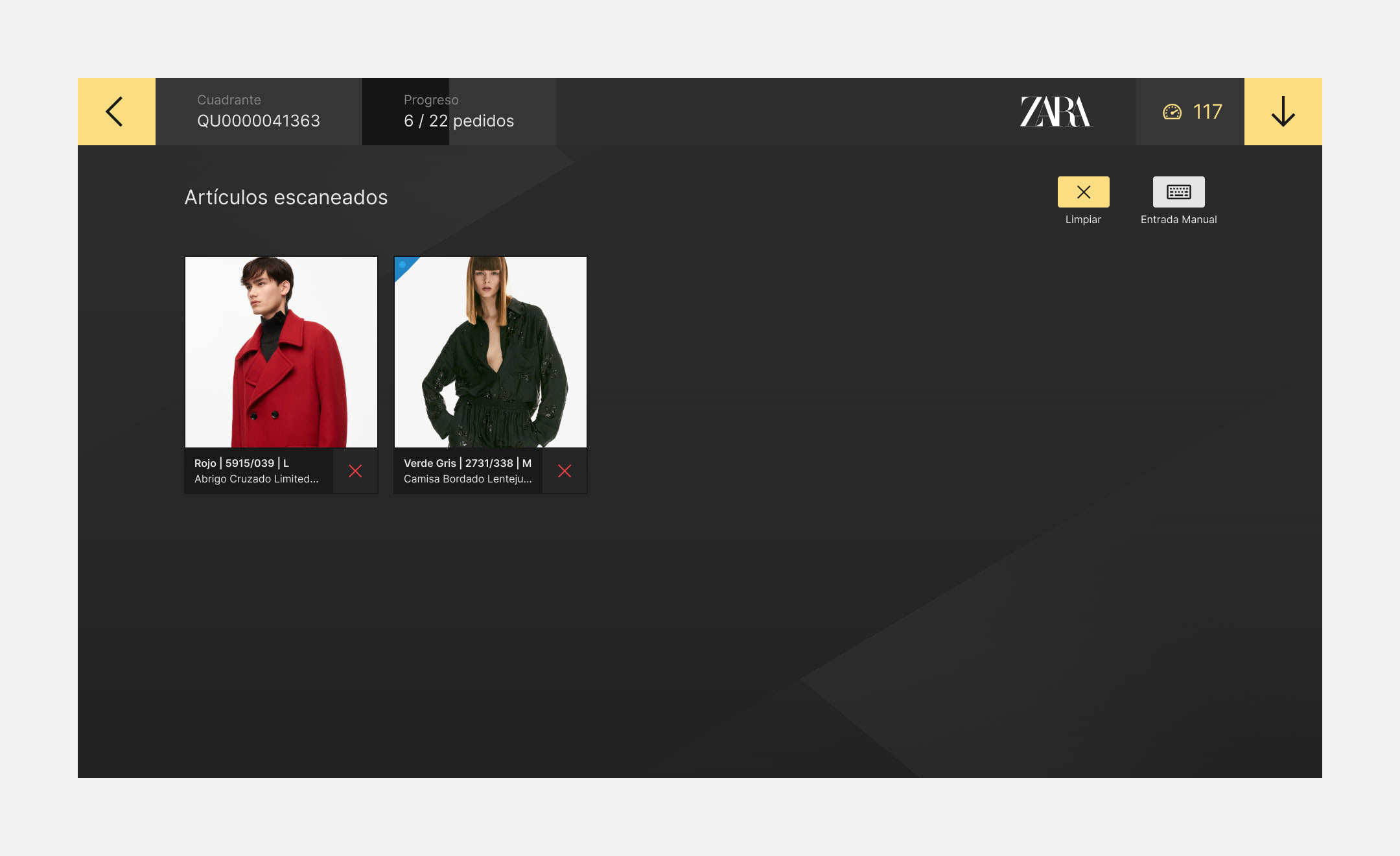

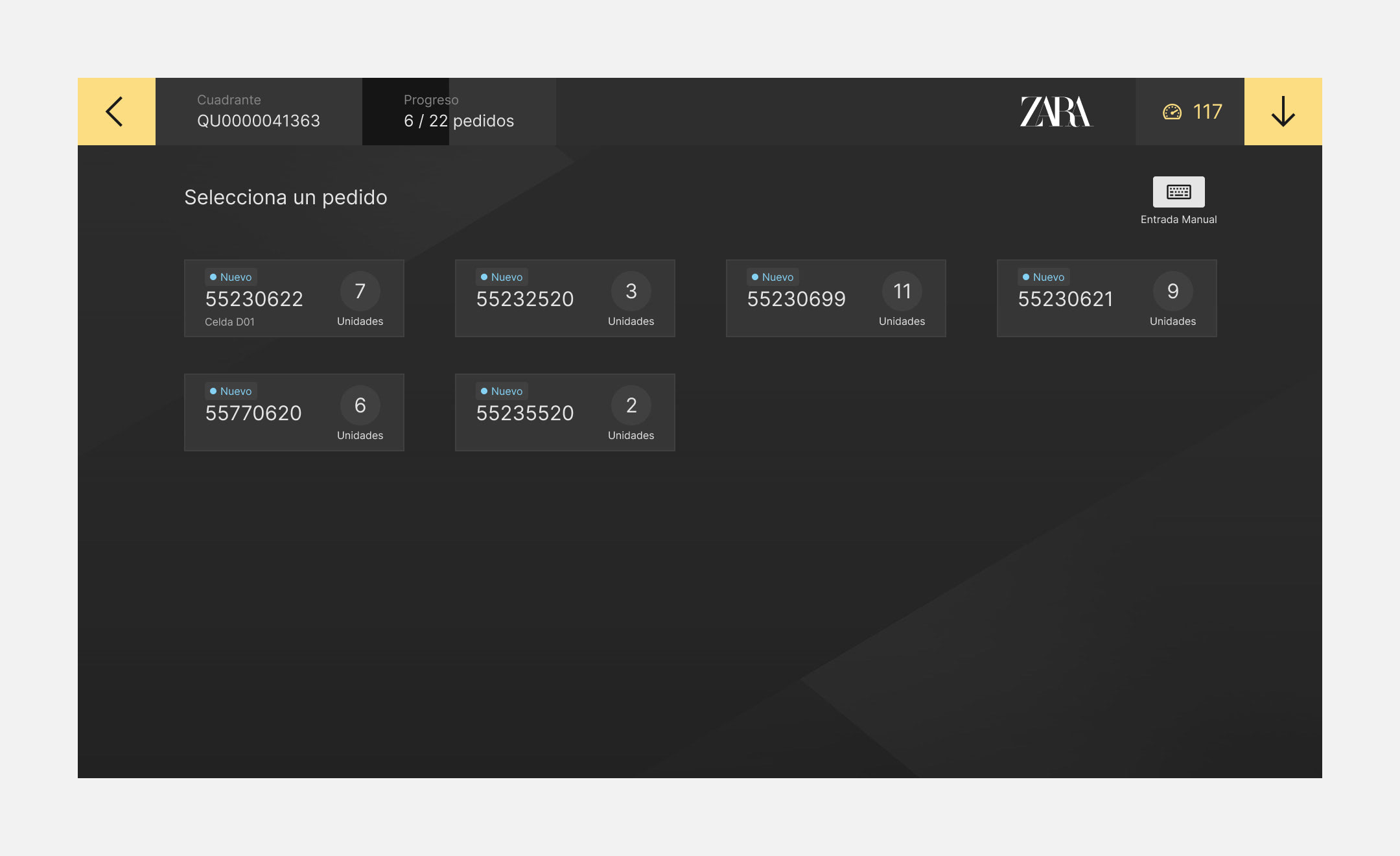

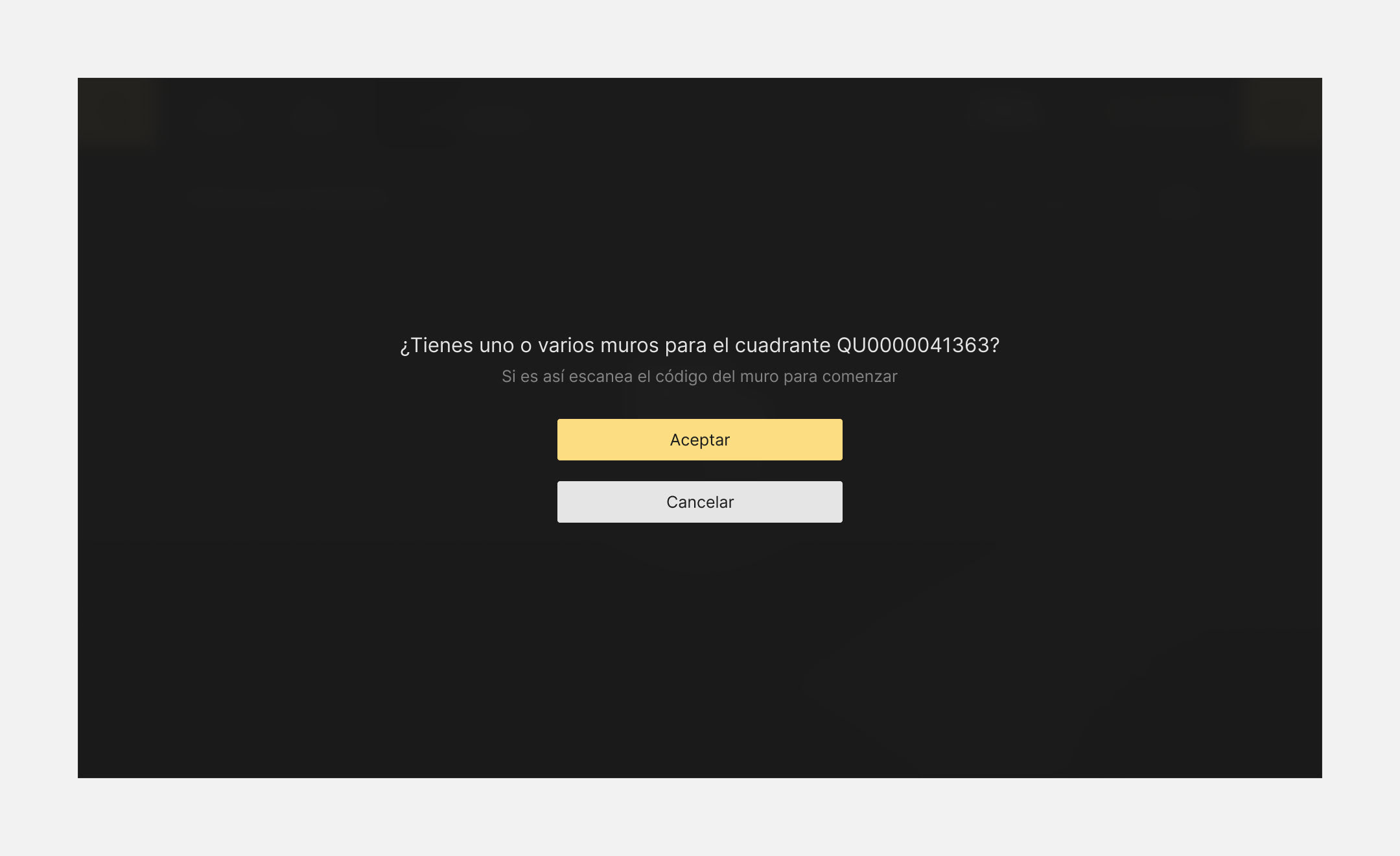

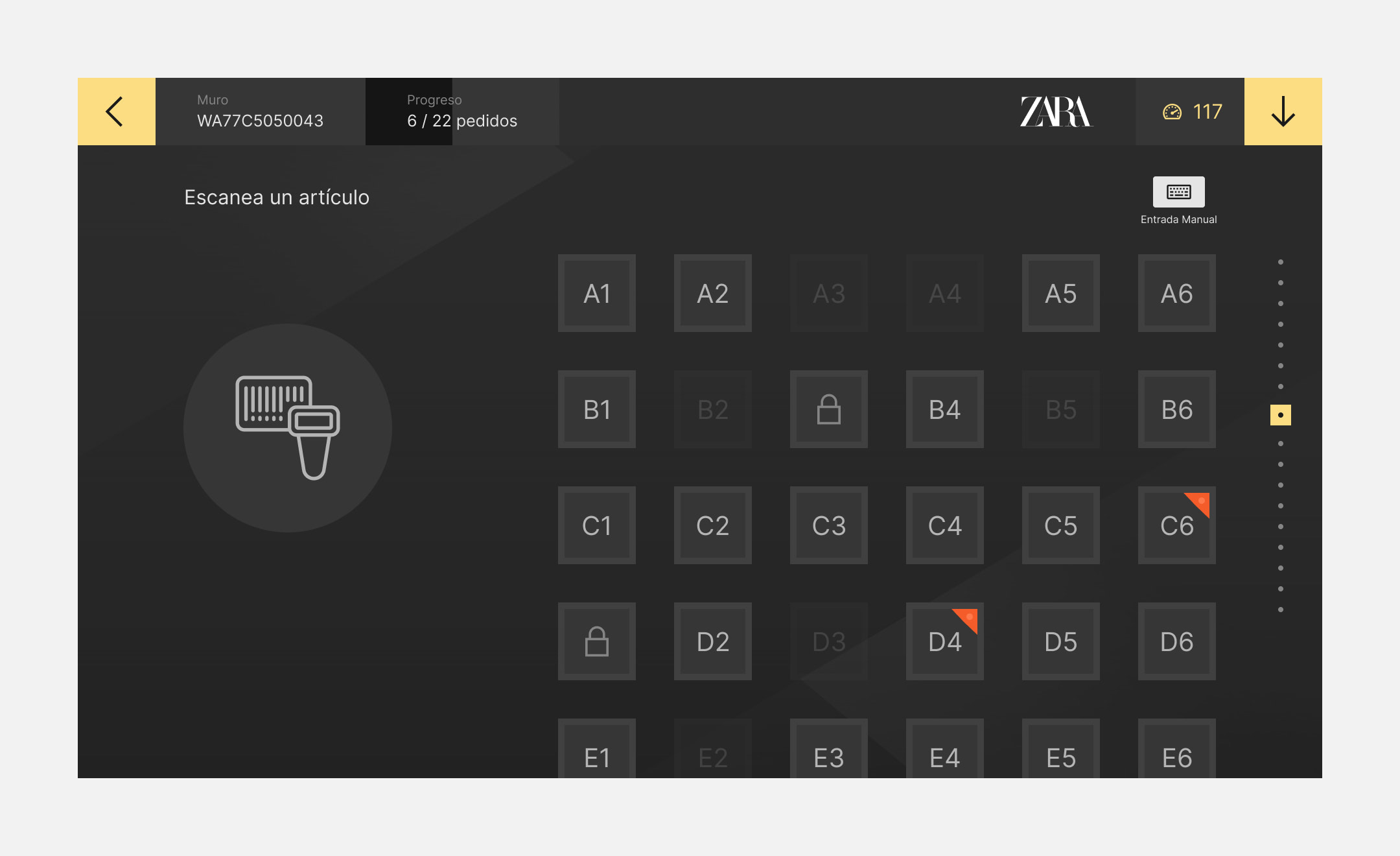

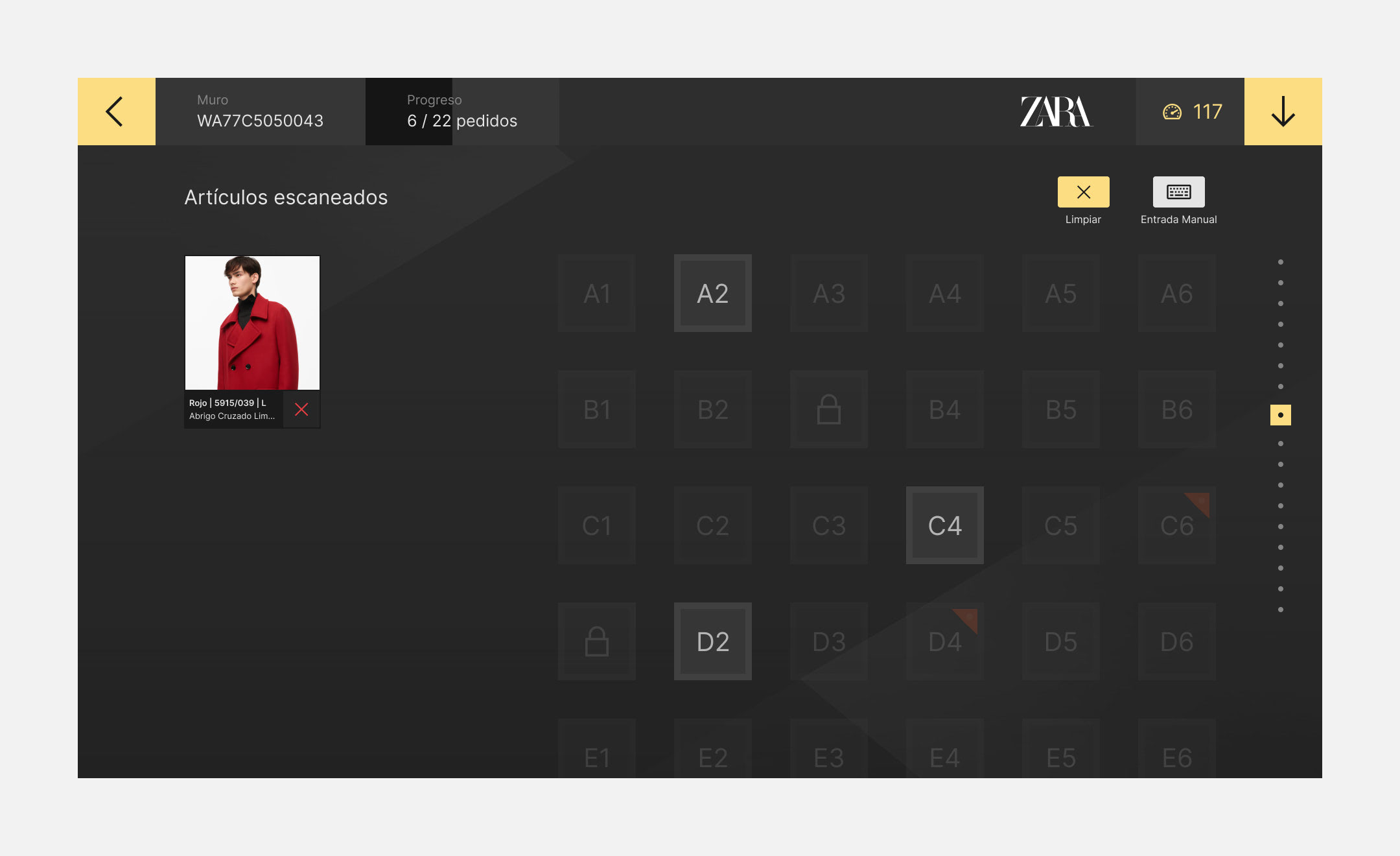

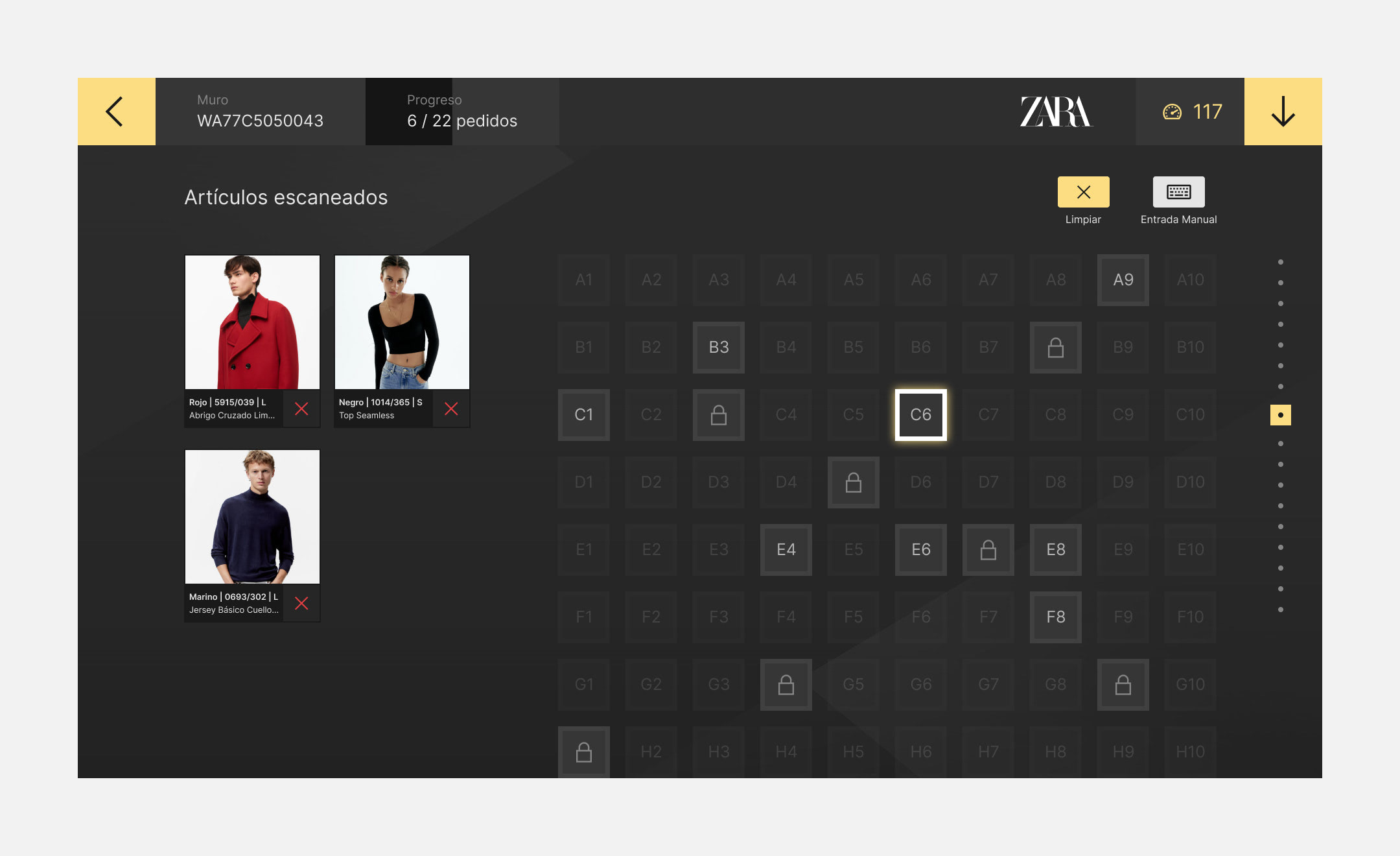

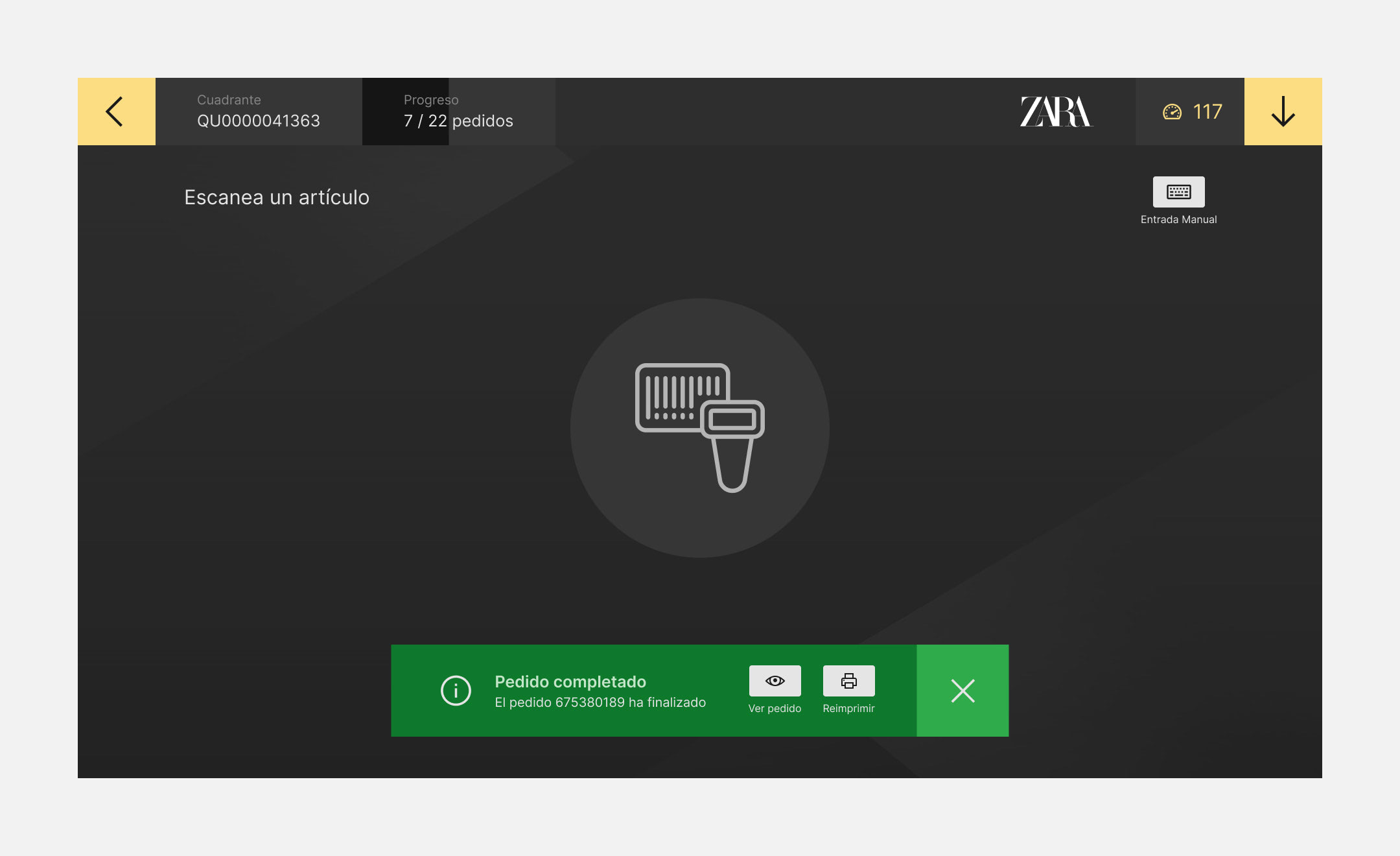

The system enables the quick identification of products through barcode scanning or manual entry by keyboard, automatically locating possible orders when scanning the necessary items. Additionally, it provides the option to scan quadrants of mobile shelves at the preparation station.

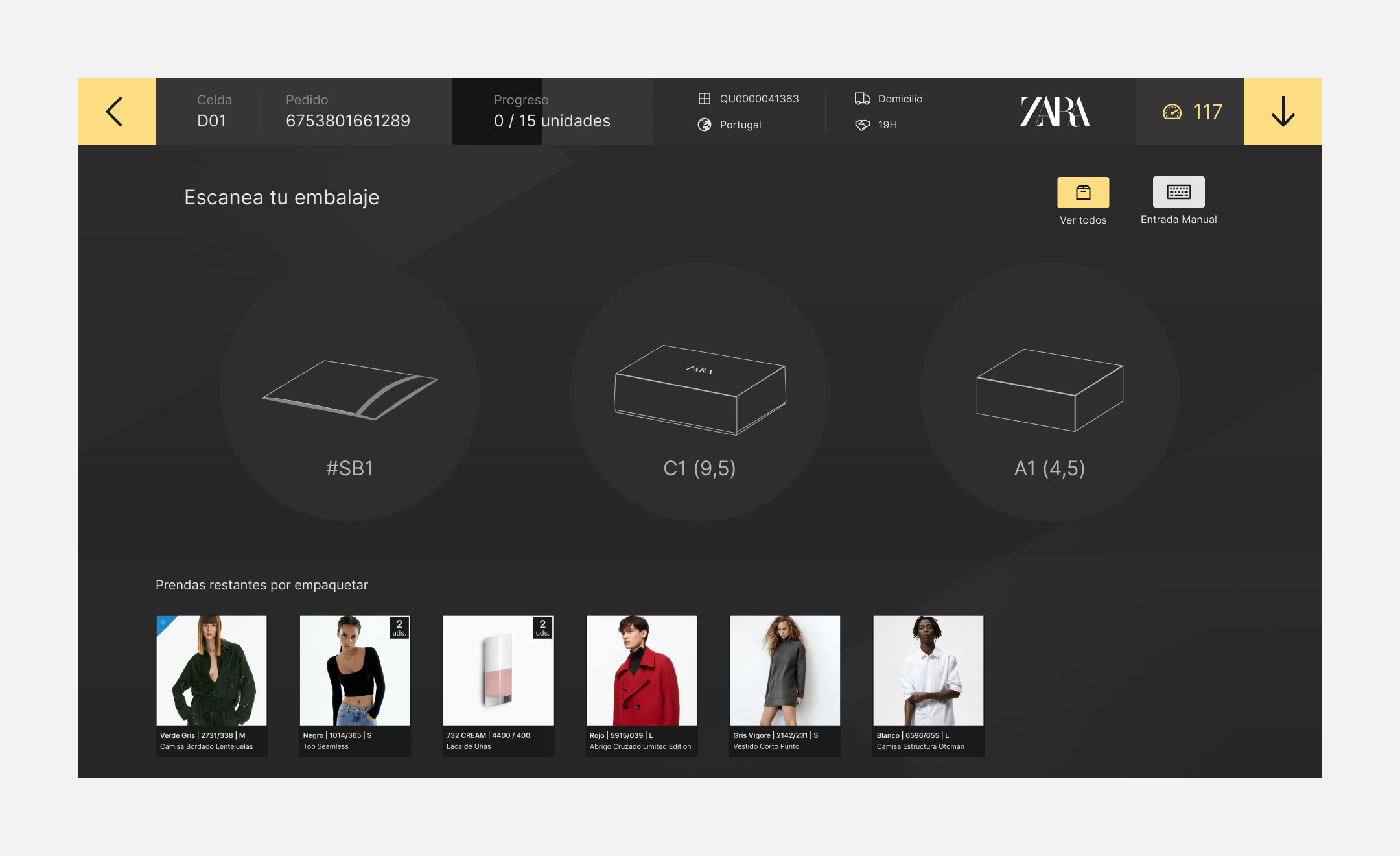

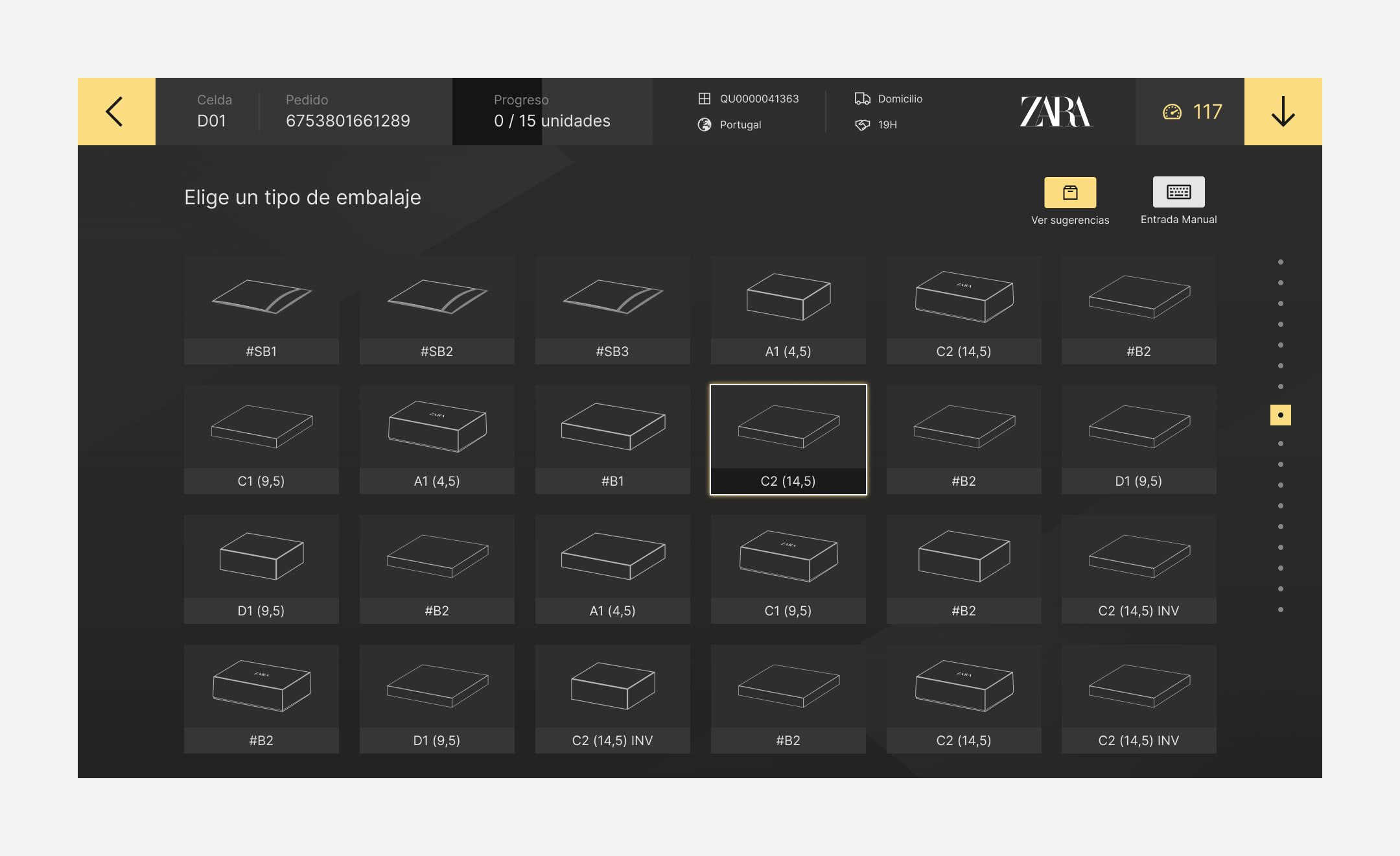

Once the order is located the system suggests a suitable packaging for packing the products. Users can manually select the packaging based on their preferences.

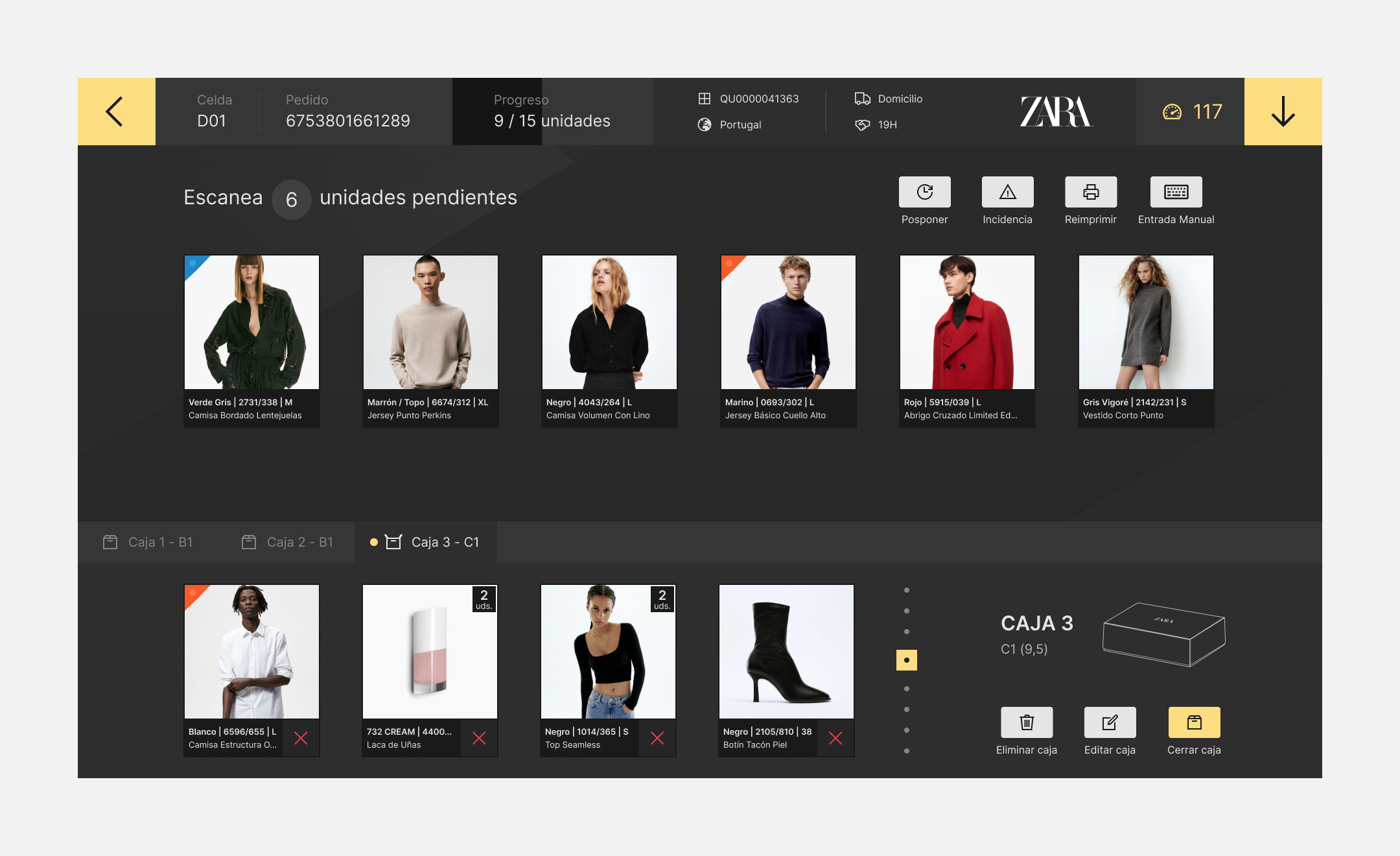

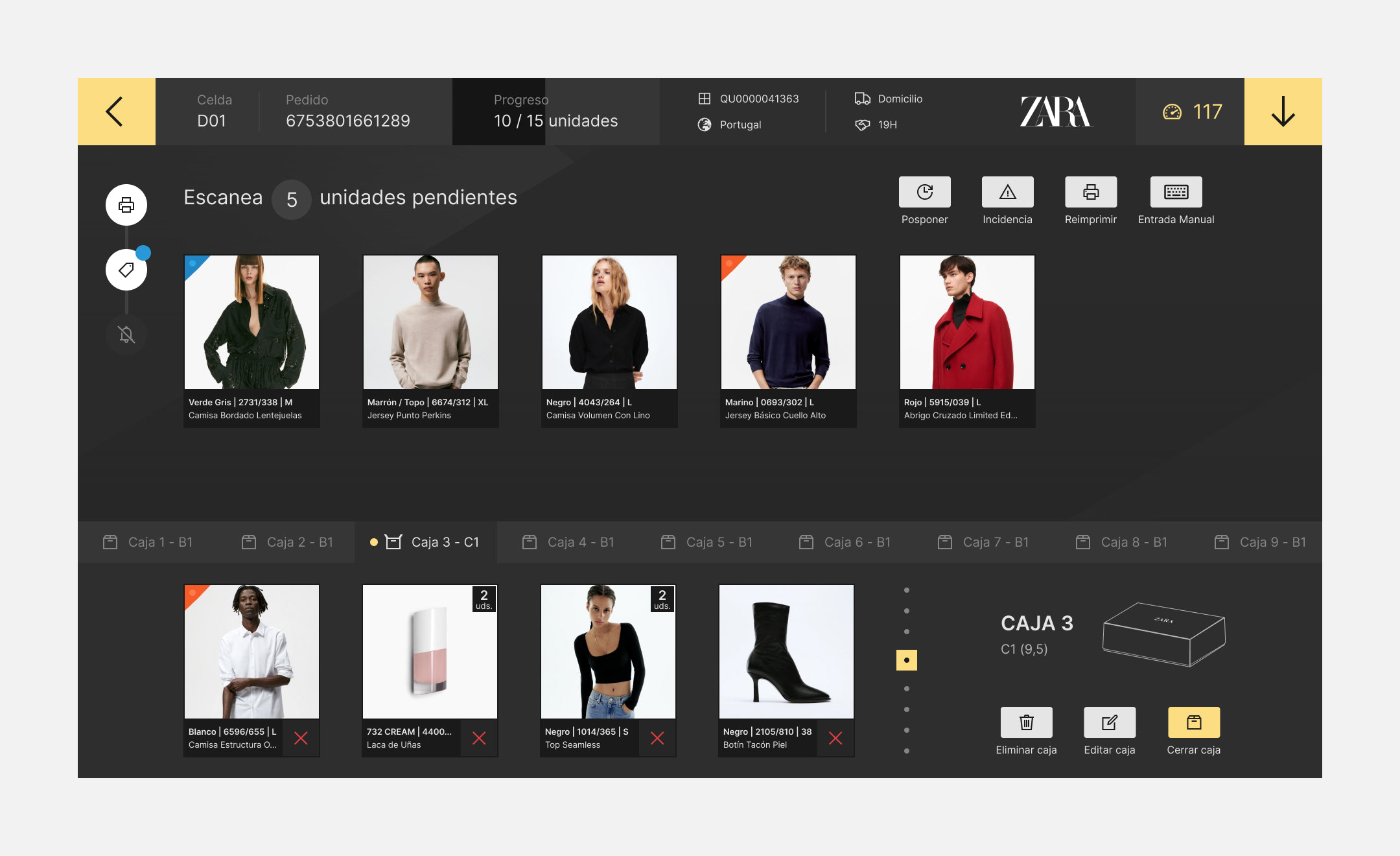

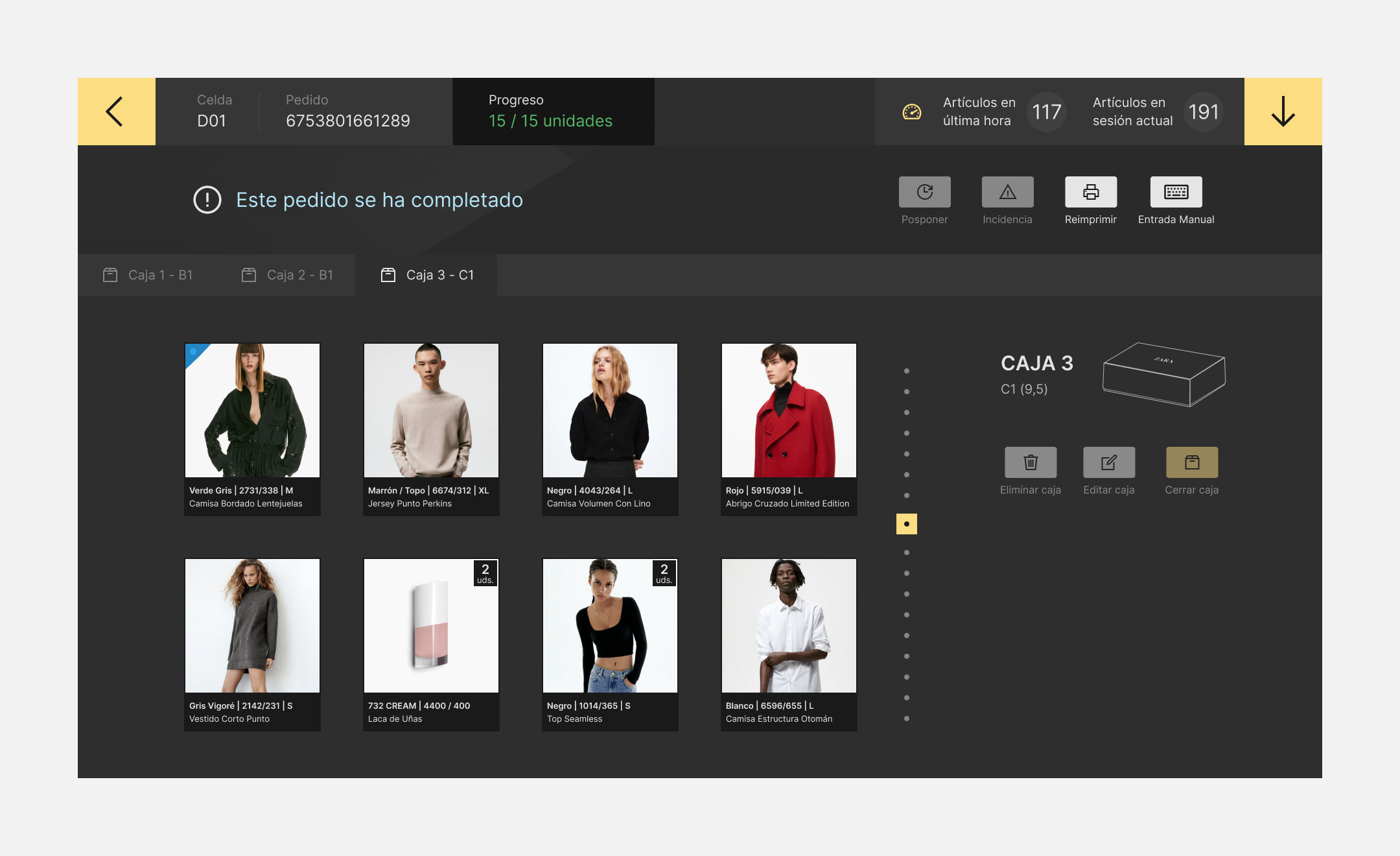

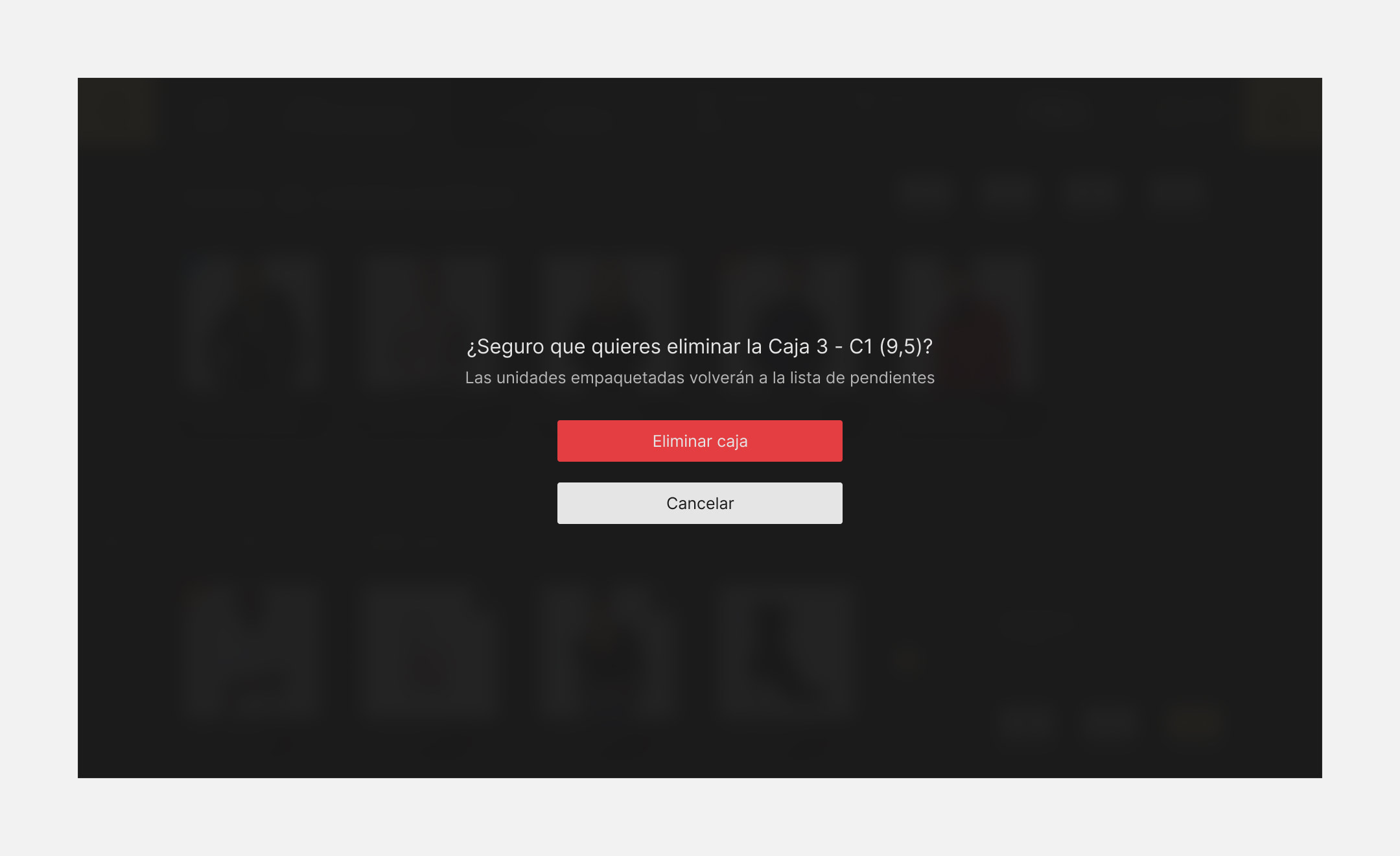

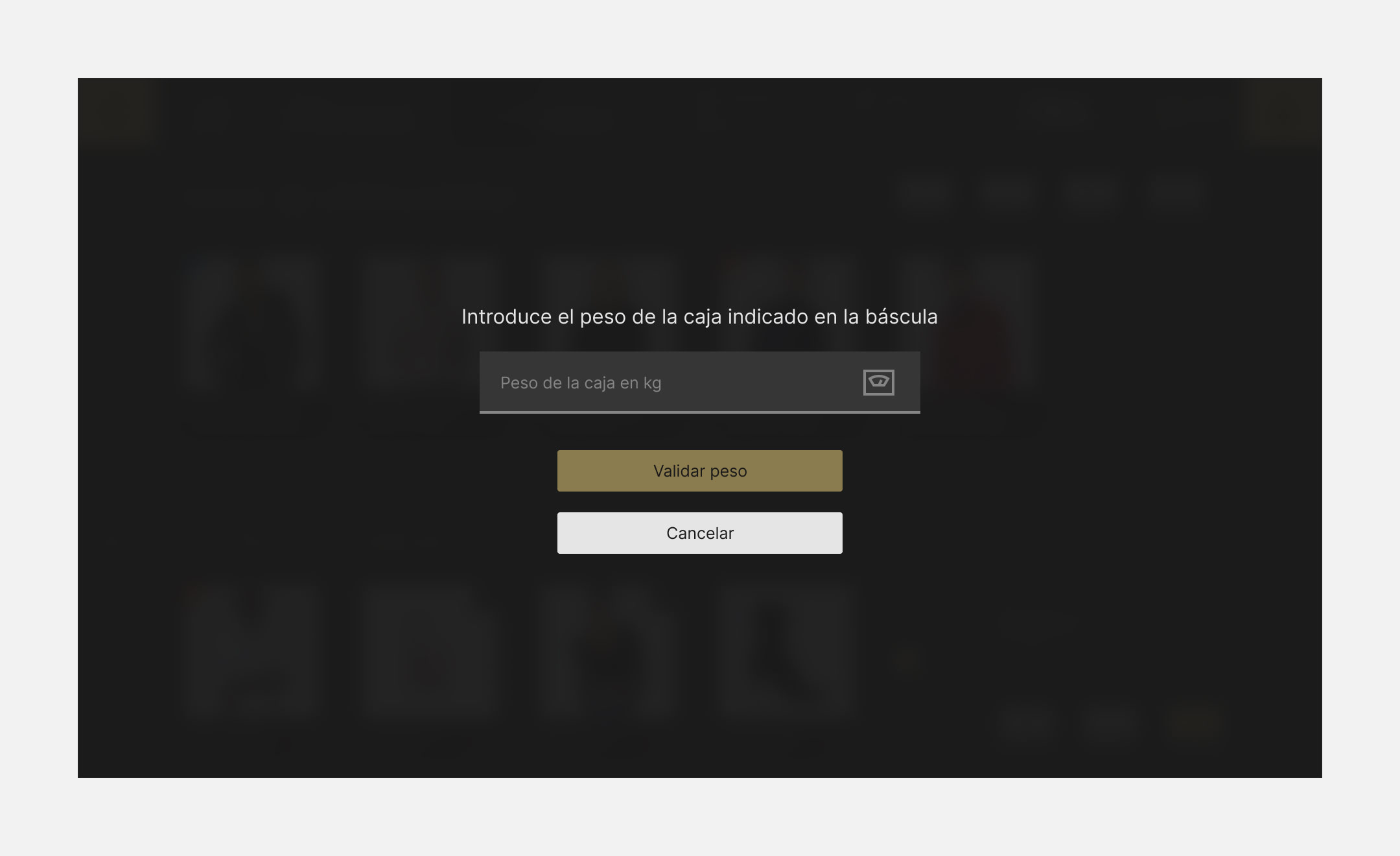

The interface displays details of packaged and pending products, provides order metadata with options to add packaging, manage issues, print labels or change orders. It also includes real-time notifications and tips, allowing packaging adjustments at any time.

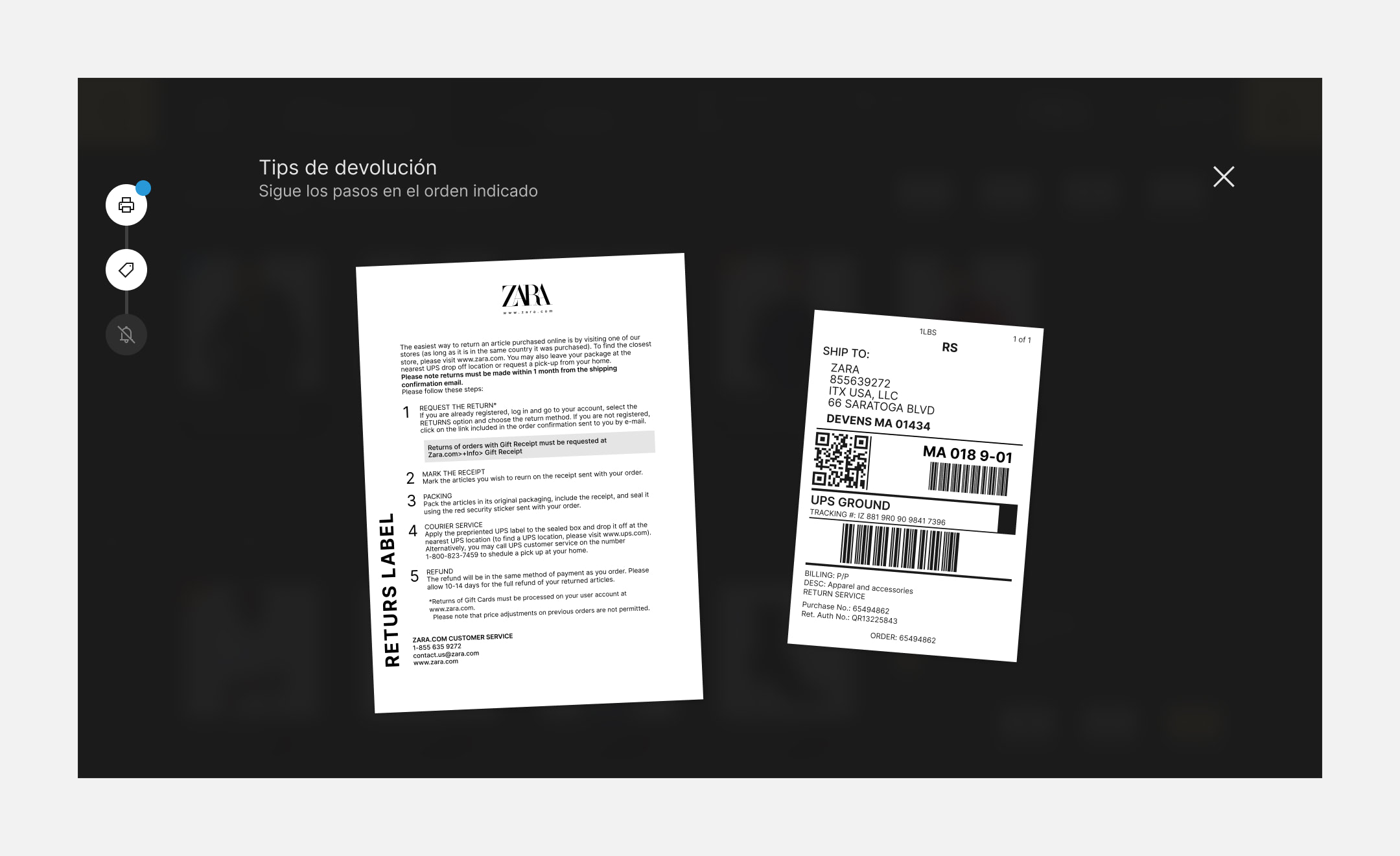

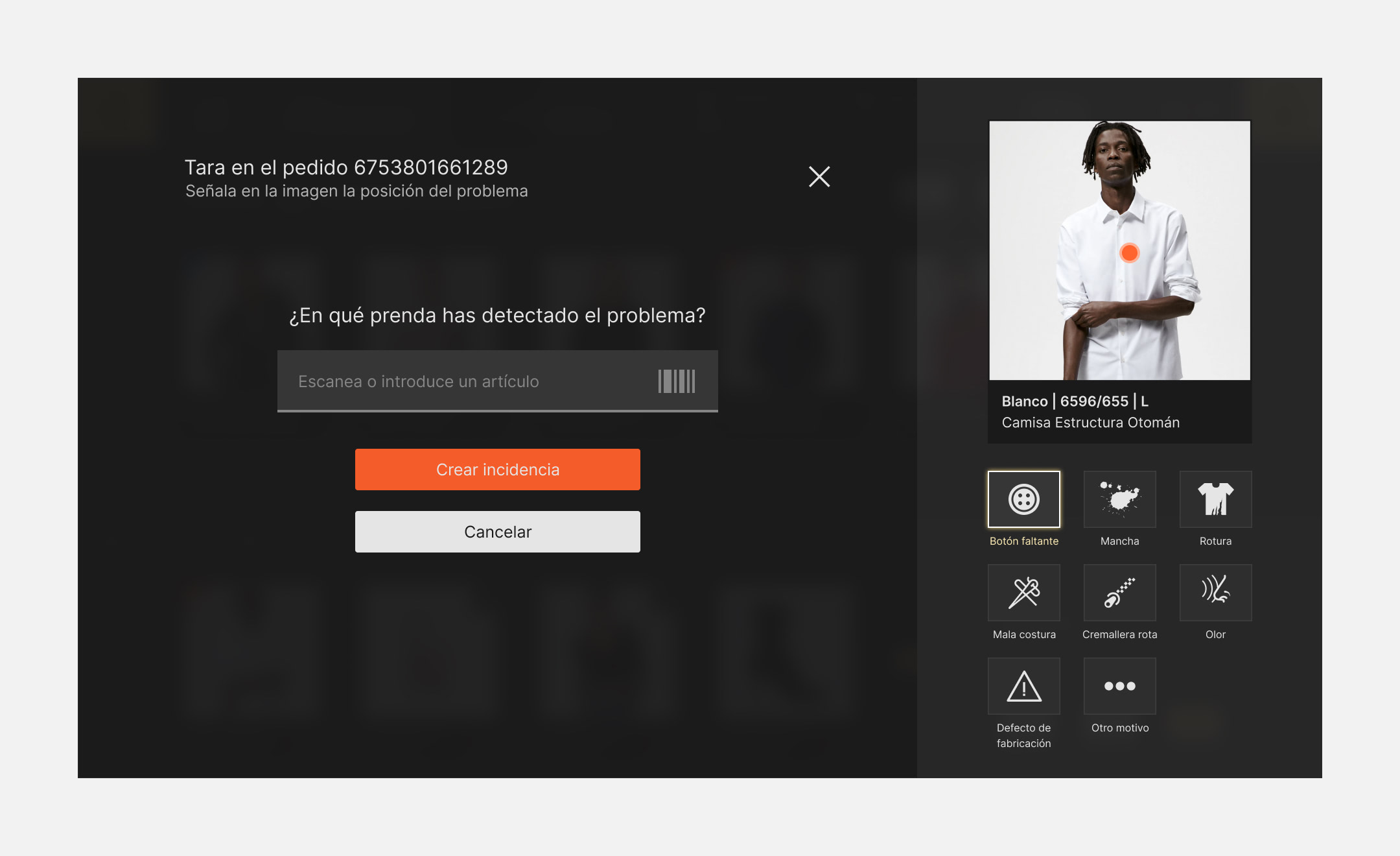

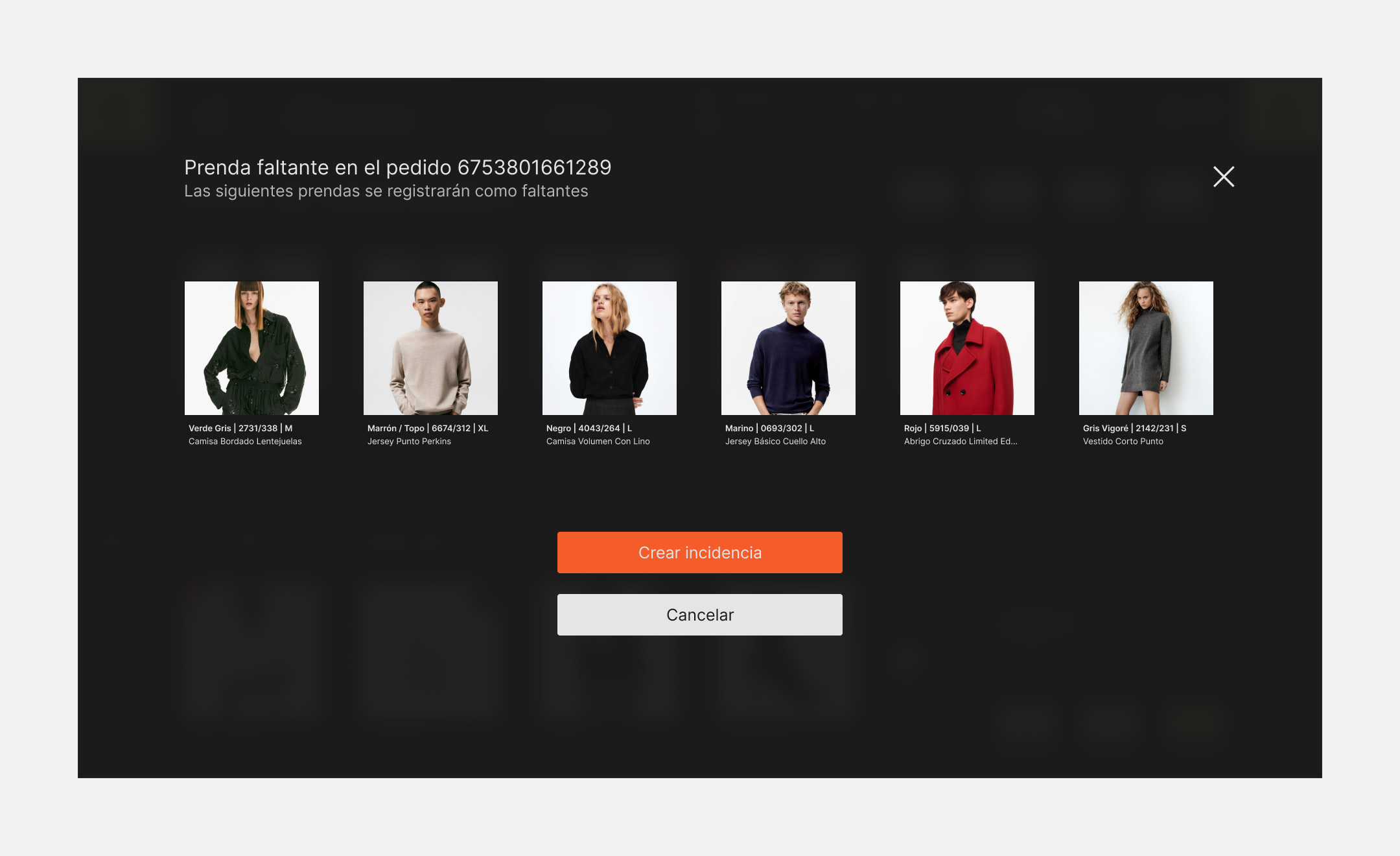

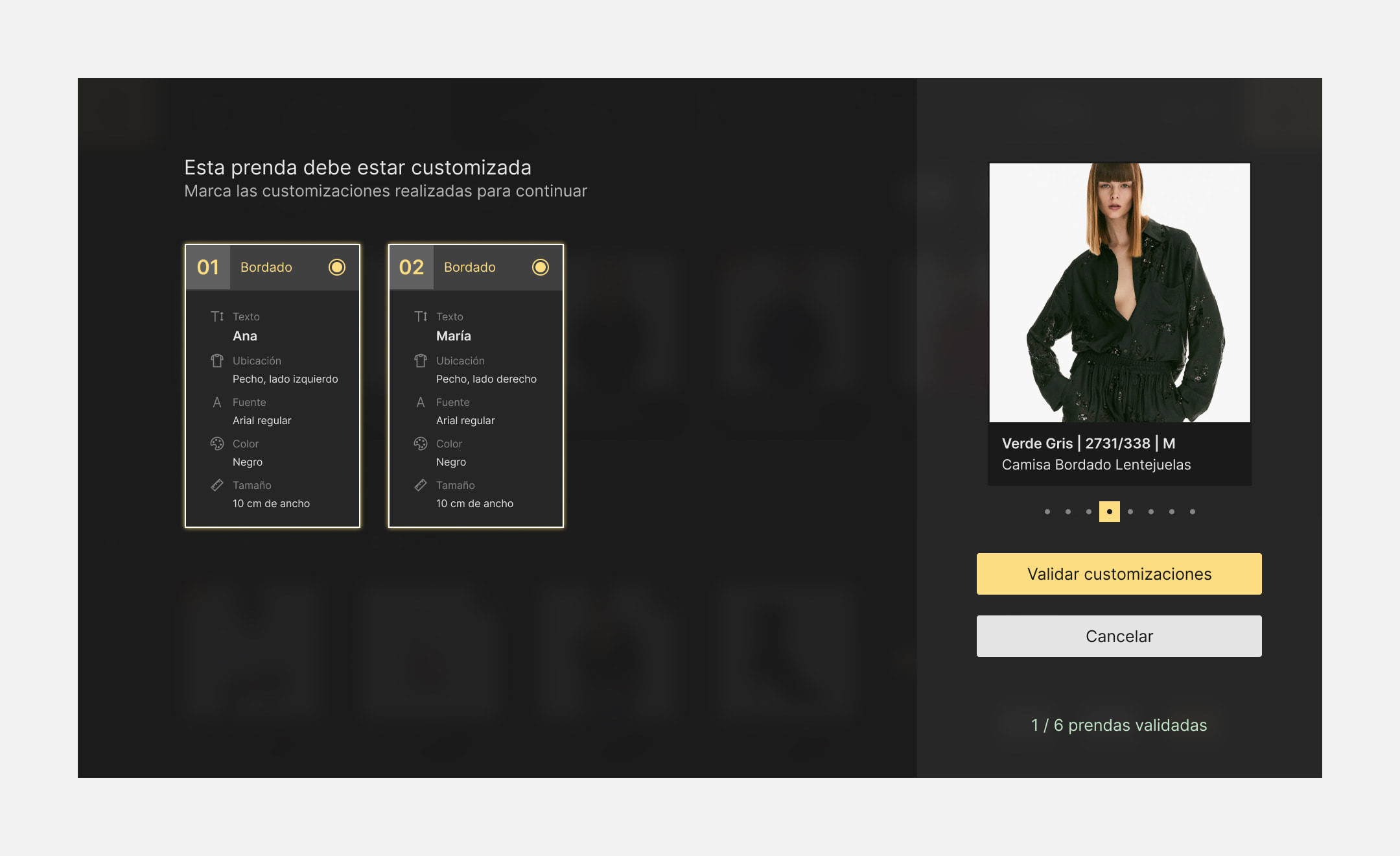

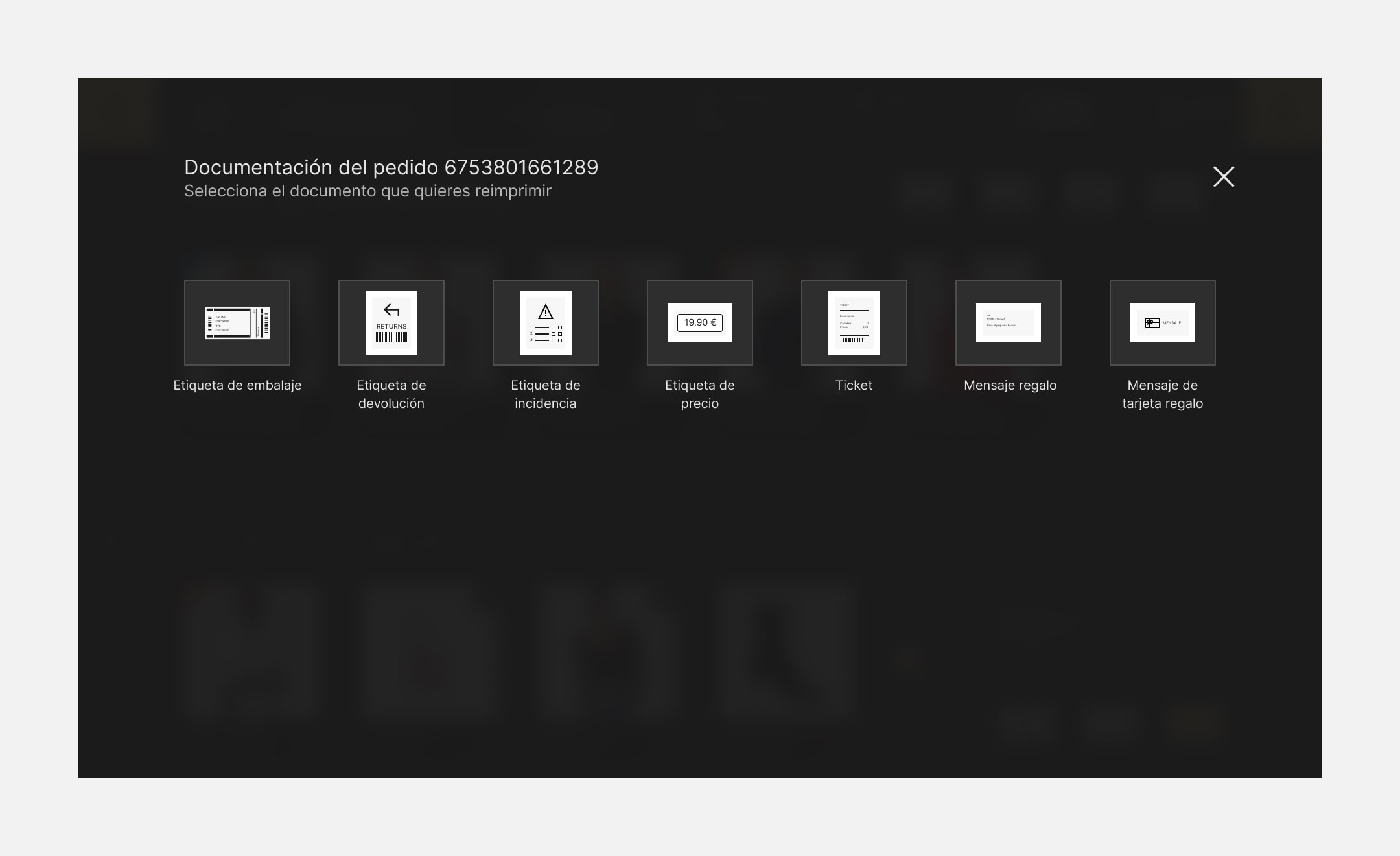

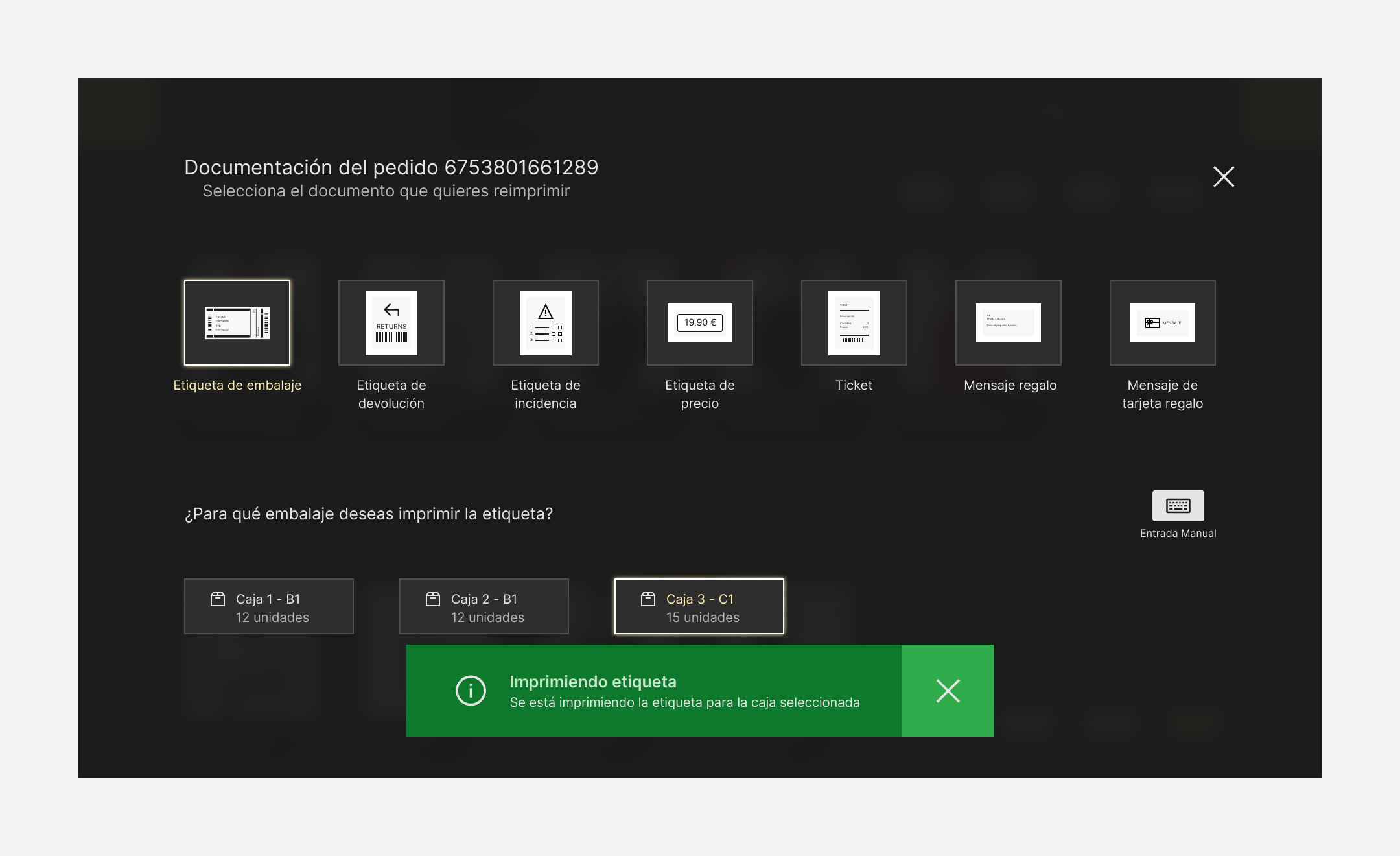

In the event of any issues with the products the system allows users to flag them, specifying the nature of the problem and the precise location on the item. There is also a functionality to report the absence of products and take corrective measures. Verification and confirmation of all customizations on the products are necessary before packaging. Lastly, at any time, users can reprint the necessary labels, tickets, or custom messages.

Do you like what you see?

Let's talk!

Check out these other projects

NextailCase study coming soon

ÁgataDigital potential comes full circle

OctoHarmonizing data in a visual way

INDITEX NOA FrameworkRevolutionizing digital creation at Inditex warehouses

INDITEX SGAElevating logistics with a stylish brand

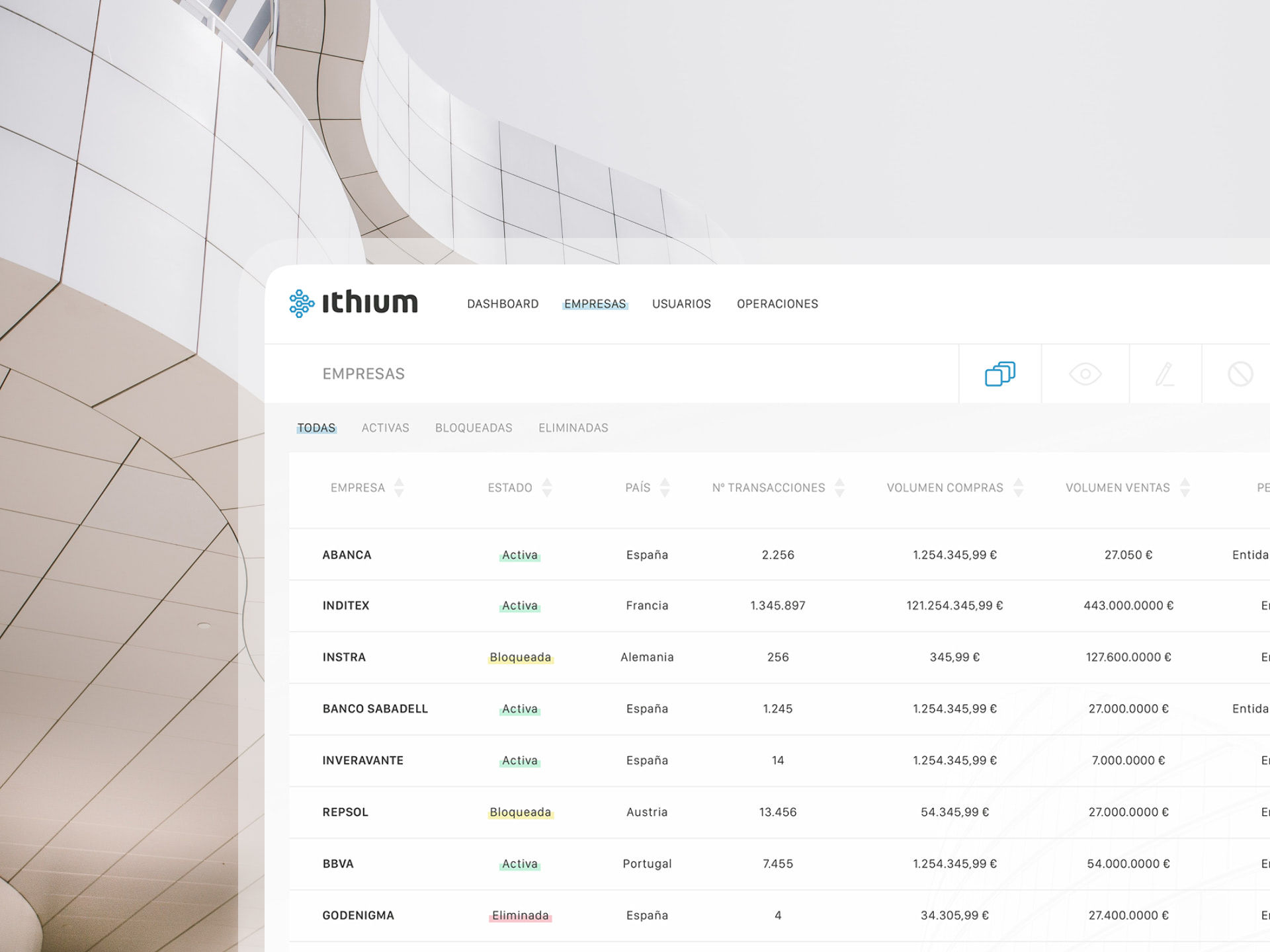

Ithium FinanceUser-centric blockchain empowerment

Abanca Open BankingAn open platform for next-gen banking

A Coruña es másUnveiling a city's essence

XingfuA digital bridge between cultures

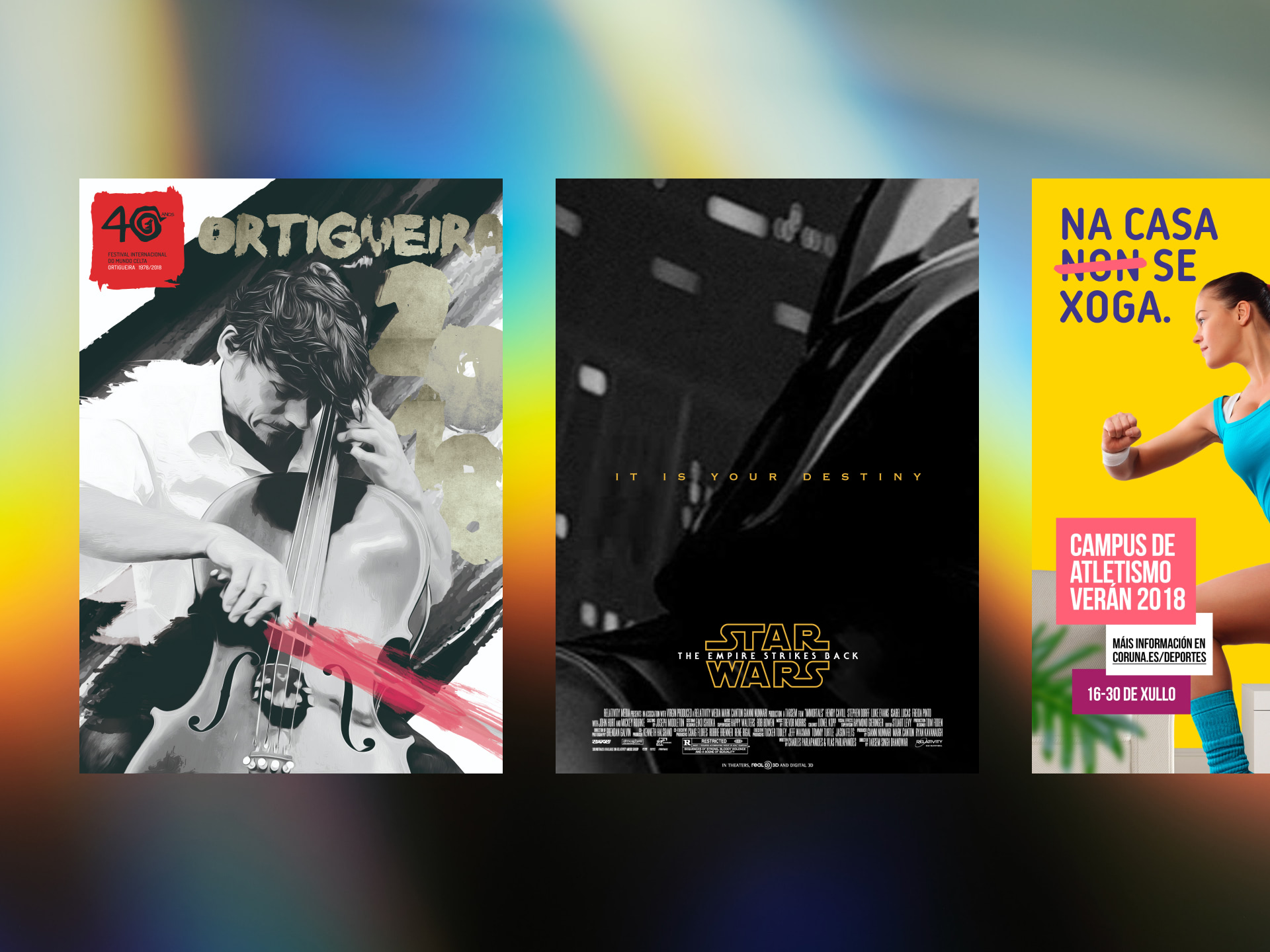

Poster CollectionCreativity meets expression

WebfolioFunctional and impactful websites

LogofolioCurated and distinct identities